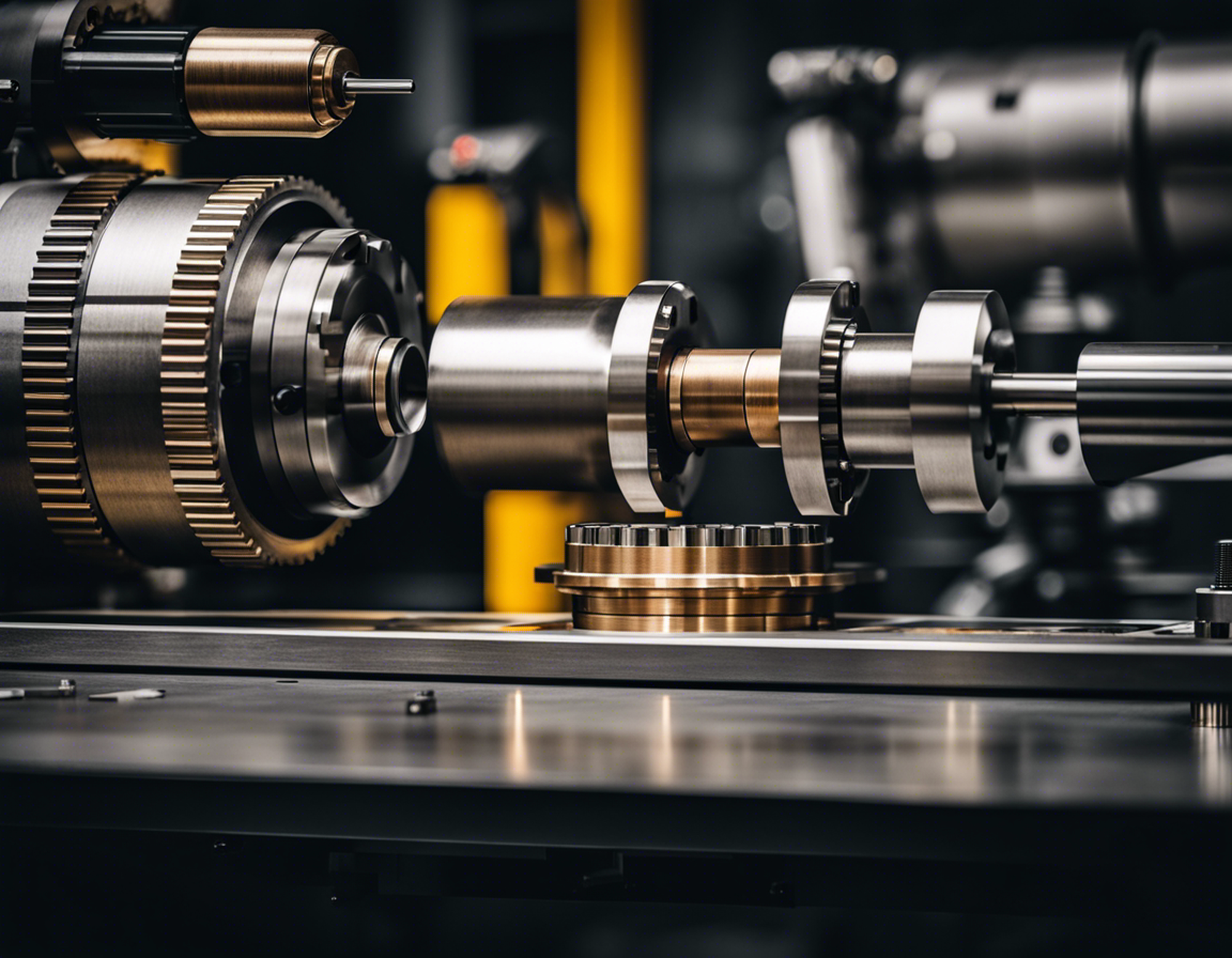

Metalworking is a complex process that requires precision and expertise. One of the crucial steps in this process is cutting and shaping metal parts to exact specifications. Three common types of machining are milling, turning, and grinding. Each has its own unique benefits and uses in the metal manufacturing industry. In this article, we will explore milling, turning, and tangential grinding, seen from the perspective of the specialized services offered by Bermec.

Bermec offers specialized services including turning, milling, and tangential grinding.

Milling, turning and grinding are essential processes in the production of mechanical components. Bermec is a leading provider of machining services for the metal manufacturing industry. In fact, the company offers specialized services in turning, milling and grinding.

Turning

In turning, Bermec uses state-of-the-art equipment to produce high-precision cylindrical parts with tight tolerances. Bermec has 3 and 4-axis CNC lathes and traditional machines available for this type of machining. We currently have 3 CNC lathes and 2 traditional parallel lathes, but with a view to continuous improvement, we have dedicated investments to two new purchases that will soon enrich our machine park. First of all, it is a vertical motorized lathe with a y axis (the first example in Italy), which will give us greater competitiveness through larger working dimensions (Ø850x900), and secondly a horizontal lathe fresh from the factory, which will guarantee us better performance, high reliability, reduced consumption and hyper-connectivity.

Milling

On the other hand, our milling services are ideal for creating complex shapes and features on metal parts. And we would like to point out that the more complex the components, the more competitive we are. For milling machining we present a large pool of 3-4-5 axis CNC machining centers (as many as 9 machines), plus 3 traditional milling machines. We have also followed the philosophy of continuous improvement for milling and in fact we invested in 2022 in the acquisition of two new machines: a 4-axis horizontal machining center that is very competitive on the processing of aluminum material (which is the raw material used for 85% of our production) and a 5-axis machining center that has allowed us to process longer lengths (up to 1530 mm).

Grinding

Finally, Bermec's grinding services use advanced techniques to achieve smooth finishes and precise dimensions on metal surfaces. Our team of experienced professionals is committed to delivering high-quality results that meet our clients' unique needs and specifications. In fact, Bermec has tangential grinding and can process flat surfaces with a maximum size of 1000x500.

Bermec is a reliable partner for metalworking

In conclusion, milling, turning, and grinding are essential processes in metal manufacturing. By understanding the basics of each process and partnering with a reliable machining service provider like Bermec, you can ensure that your project is completed accurately and efficiently.